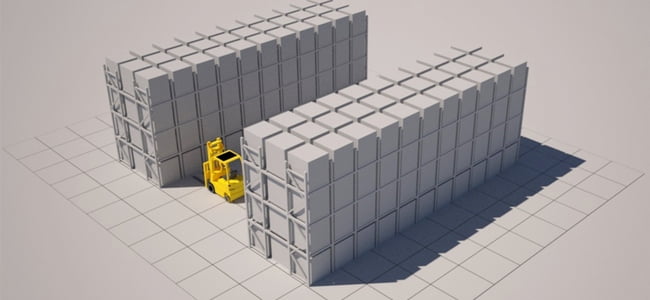

Push Back Racking

Overview of Push Back Racking

Push Back Racking allows six pallets deep to be stored per level. All of the pallets of each level, except the top one, are placed on a set of trolleys that are pushed along rolling rails. This means unlike Drive In racking you can pick from any pick face and as you do not have to drive in the rack it makes picking and putting away quicker.

Push back racking can be a very space and time efficient option. Pallets are loaded from the front onto either wheeled carts or rollers and then the pallet is pushed back. The system only works as LIFO system.

Features of Push Back Racking

Specifications of Push Back Racking

Uses of Push Back Racking

Push Back Racking is generally used in marshalling areas and for bulk storage it is ideal to fill a void where it is not possible to get another full aisle in. Push Back Racking is ideal for storing medium-turnover products, using the Last In First Out (or LIFO) system.

Drawbacks of Push Back Racking

This is a moving system, so beware that things can go wrong. Debris can get onto the roller track causing the trolleys to jam. If pallets are put away incorrectly then you can cause the trolley to twist and jam. This system needs to be maintained. Also, because this system is specialized and some forklift operators have not used it before we recommend that training be given.